Reach the next level

Our future depends on how efficiently we use what we already have. We help manufacturers reduce waste, improve quality, and increase yield with AI-powered vision systems.

*Consultations are free

Try our analysis yourself

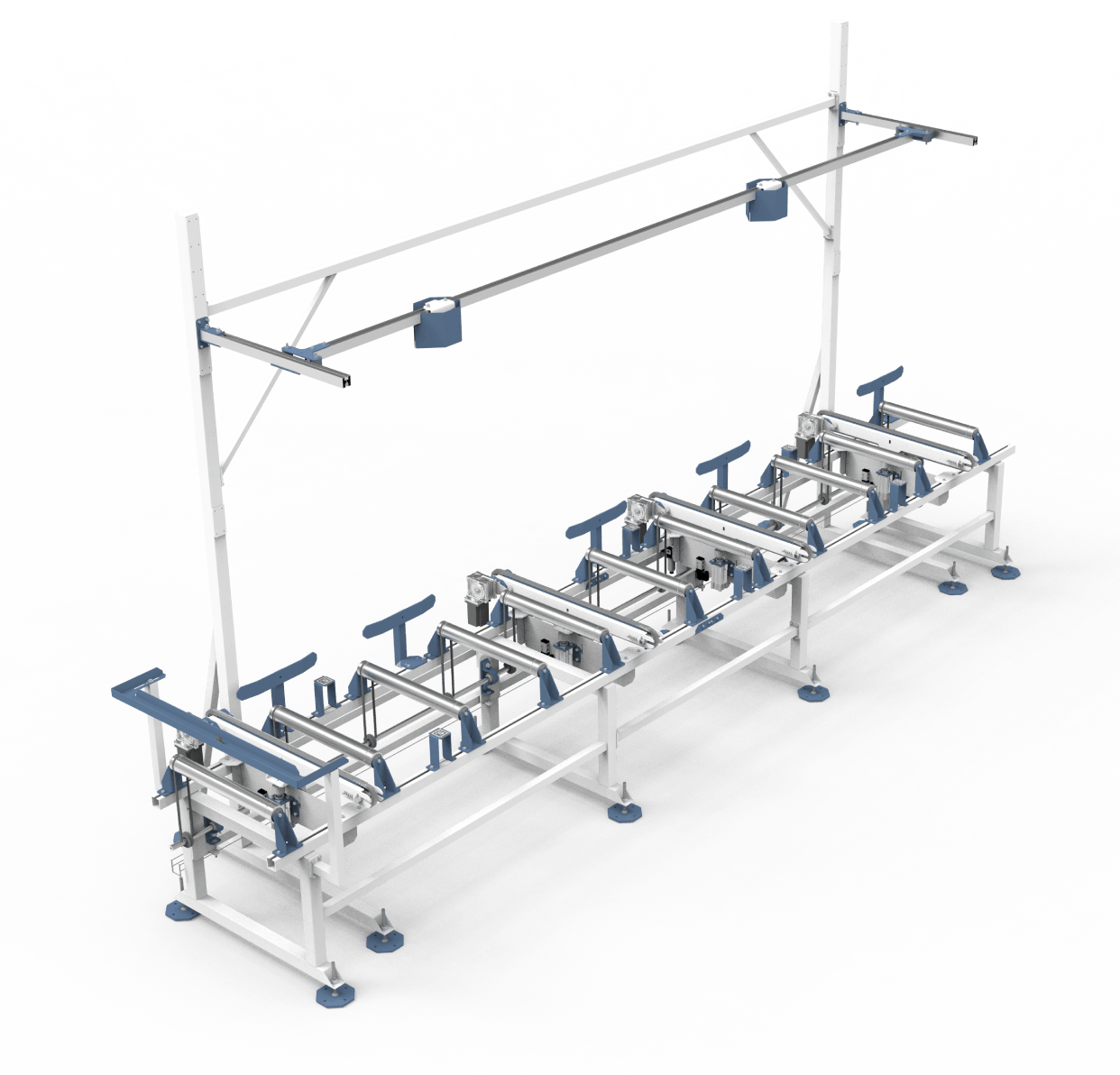

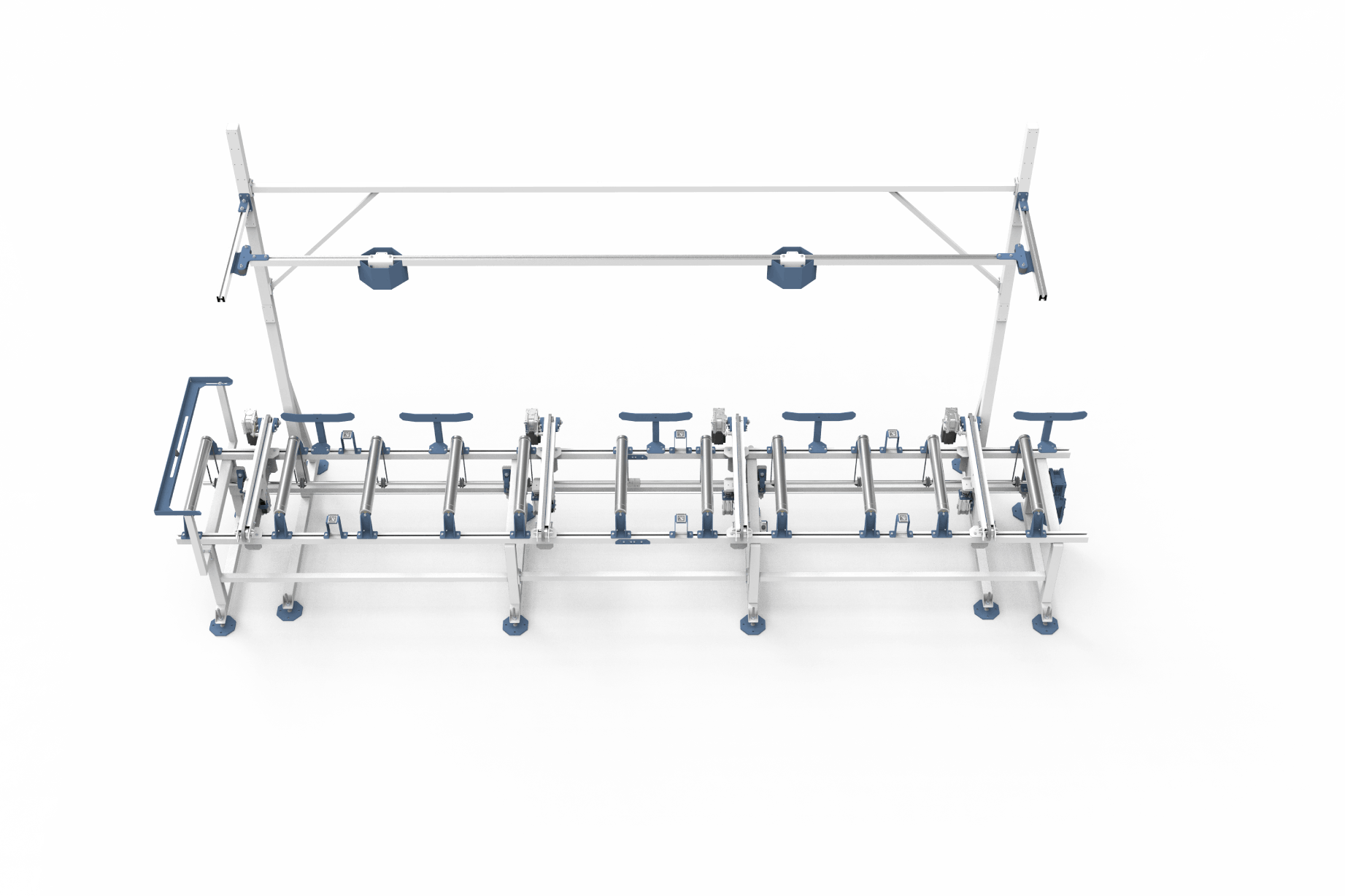

An inline AI vision system that precisely aligns rough boards before a multi-saw, maximizing yield and minimizing waste at full production speed.

How does it work in 4 steps?

An inline AI vision system that precisely aligns rough boards before a multi-saw, maximizing yield and minimizing waste at full production speed.

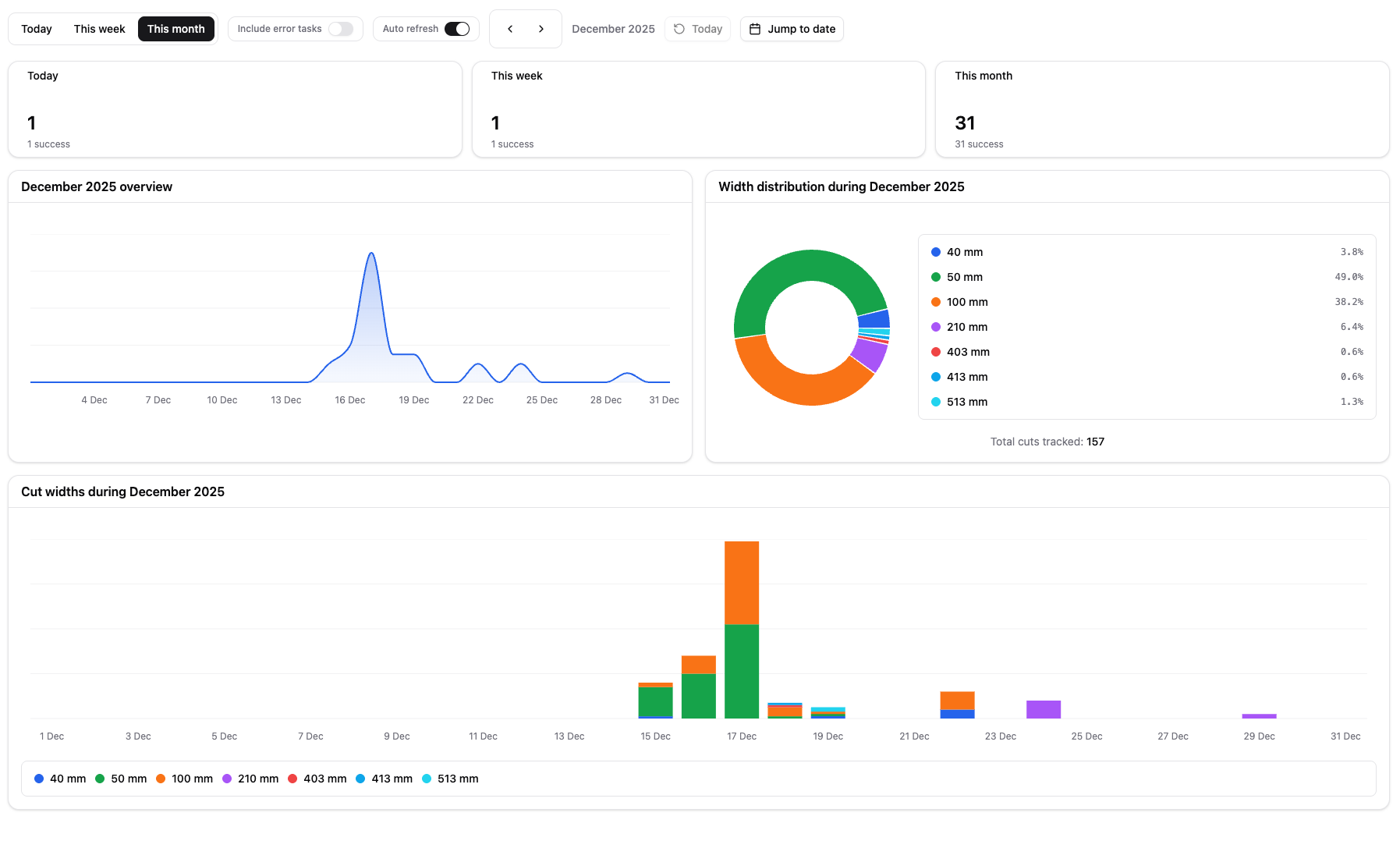

Full analytics

An inline AI vision system that precisely aligns rough boards before a multi-saw, maximizing yield and minimizing waste at full production speed.

General insights

A shared view of production performance, quality, and efficiency for operators, engineers, and managers.

Full control

Sagittis sit suspendisse fames sed semper vitae consequat id tempus.

Control panel

Sit ieu lutpat venenatis vehicula sagittis turpis.

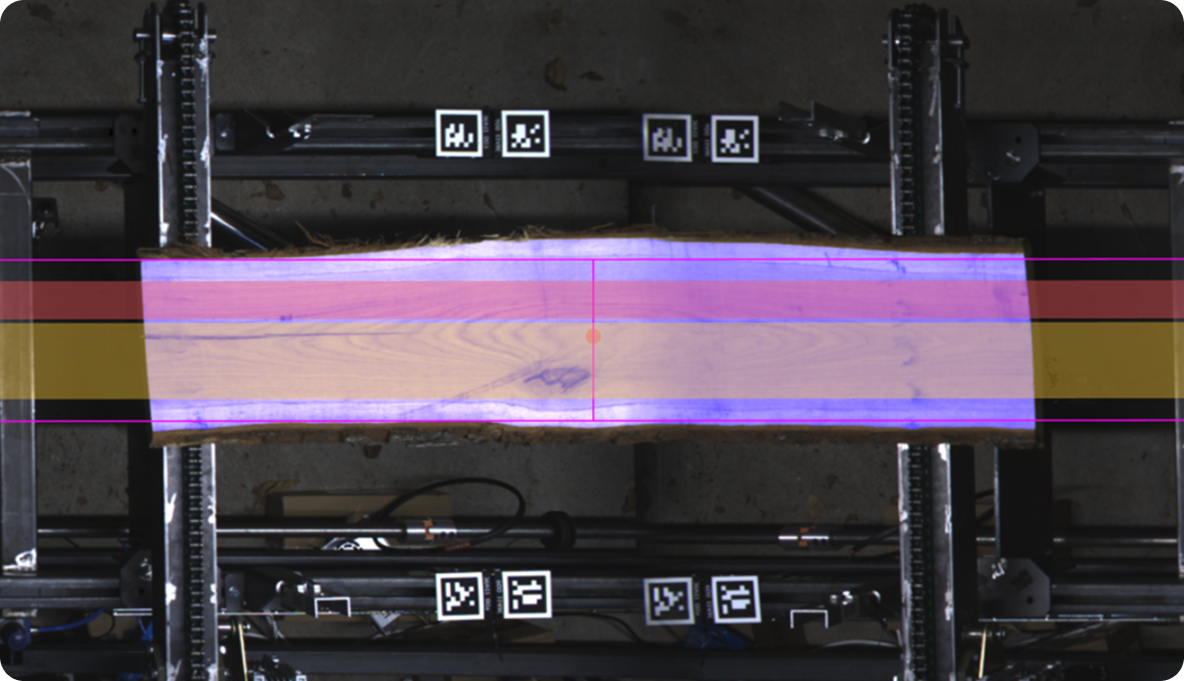

Board analysis

Inline geometry and defect insights to align boards precisely and maximize yield.

Defect detection

Arcu felis venenatis aenean eget nisl id condimentum. Etiam amet mi mattis posuere eu aliquet quam bibendum.

Numbers don't lie

An inline AI vision system that precisely aligns rough boards before a multi-saw, maximizing yield and minimizing waste at full production speed.

Our vision

Our future depends on how efficiently we use what we already have.

We help manufacturers reduce waste, improve quality and increase yield using AI-powered vision systems.

Wood Edger. An inline AI vision system that precisely aligns rough boards before a multi-saw, maximizing yield and minimizing waste at full production speed.

Reduce waste, maximize profit. By combining advanced vision algorithms and deep learning, we optimize processes to increase material yield, improve product quality, and reduce waste at the source.

Fully automated. Our vision systems run fully autonomously, integrated directly into production lines. Consistent performance, maximum uptime. No operators required.

Track your resources. Our dashboards give operators, engineers, and managers a shared view of production performance, quality, and efficiency. We allow you to gain insights from anywhere, fully remote.

See how much you can save. Discover how xpection improves yield and reduces production losses.

FAQ

What exactly does the Xpection station do before the multi-rip saw?

It automatically locates the board or cant, calculates the optimal alignment for the cut, and corrects position and angle so the material enters the multi-rip straight and consistently.

Does it work if the multi-rip saw has fixed settings (fixed widths)?

Yes. This is one of the main scenarios. You do not need to rebuild the saws because we improve the infeed alignment before the cut.

What problems does it solve in practice?

Most often: material drift on the infeed and yield loss; variation in width/quality and extra trimming or sorting; downtime for manual corrections; operator errors and lack of repeatability between shifts.

What results can we expect?

Typically: higher yield, less waste, and higher throughput (m3/h) thanks to stable feeding and fewer corrections. Exact numbers depend on material and the current line state, so we propose a quick before/after KPI check.

Does it require rebuilding the whole line?

No. It is designed as a retrofit to fit existing transport and multi-rip operation, with signal integration (start/stop/ready). The scope is defined after a short qualification.

How does integration with PLC and safety work?

We integrate standard line signals: ready, start, stop, interlocks, and operating modes. In practice the station works like a normal line module with safe stop and restart logic.

What materials can it handle?

The station is designed for sawmill reality: typical boards or cants (pine, spruce, and others). Min and max ranges are defined at the offer stage based on three data points from your plant.

What is needed for a preliminary quote?

Just three items: material range (min/max plus species), throughput in m3/h and number of shifts, and a 30-60 s photo or video of the infeed to the multi-rip saw.

What is the next step if I want to check it?

First we send a demo video, then we do a 20-minute qualification call. If it is a fit, we recommend a paid on-site pilot/test or direct deployment.

What is the pilot (paid test)?

A fast ROI check: audit of the infeed and sources of material drift, KPI measurement, and an integration plan with a recommendation on whether to deploy. If you proceed, the pilot cost can be credited toward the project (as stated in the offer).

Do you have case studies and references?

At the moment we have a demo video and pilots or implementations without public publications. In the call we show examples and discuss the scenario for your line.

How long does implementation take?

It depends on integration depth and line conditions (space, transport, controls). After the call and your materials we provide a realistic schedule from preparation through commissioning and training.

Will it reduce multi-rip throughput?

The goal is the opposite: fewer manual corrections and stoppages mean steadier feeding and usually higher m3/h. We match the operating mode (stopped or in-line) to your line speed.

Will operators be able to handle it?

Yes. The system is simple: the operator selects a mode or recipe and the rest runs automatically. Training for operators and maintenance is included.

Do you collect data and KPIs?

Yes. We can collect simple KPIs (yield, waste, downtime) so you have hard numbers, not just impressions. This also becomes the basis for further optimization.

What does service and maintenance look like?

Standard: commissioning, training, and post-deployment support. The service scope and SLA depend on whether you run 1/2/3 shifts.